Split Butterfly Valve

Beta Protective Cover

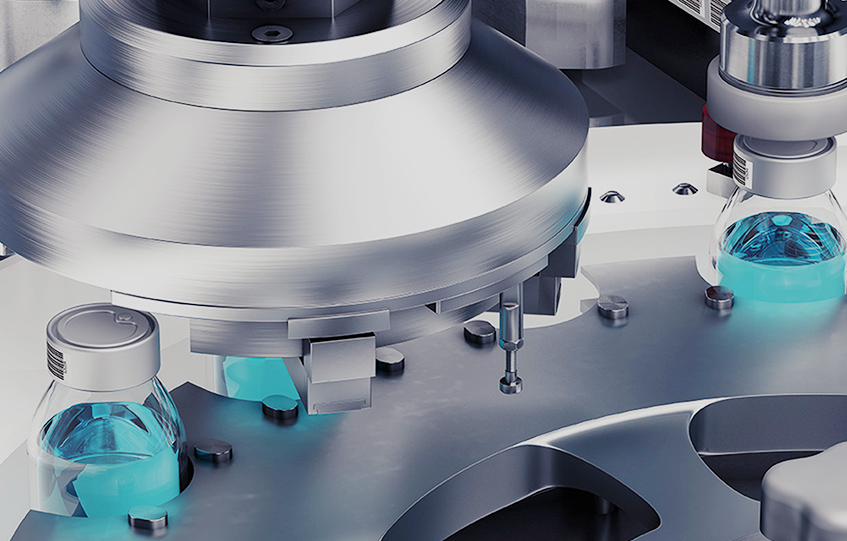

In industrial automation and fluid handling systems, the protective cover (Beta protective cover) plays a vital role. It can effectively protect the Alpha valve from external contamination when not in use, ensuring that the system maintains a high standard of sealing during the cleaning and sterilization (CIP/SIP) process. Under normal working conditions, the active valve Alpha precisely controls the flow of fluid, and when it is shut down or not in use, the Beta protective cover automatically covers the valve disc interface to prevent air, dust or other contaminants from entering the system. This not only ensures the long-term service life of the valve, but also greatly reduces the cost of maintenance and cleaning. The design of the protective cover takes into account the requirements of CIP (cleaning in place) and SIP (sterilization in place) processes. CIP/SIP systems usually involve high-temperature and high-pressure water flow, chemical cleaning agents or disinfectants when cleaning industrial equipment, which places high demands on the sealing of the valve. The Beta protective cover can keep the Alpha valve disc interface completely closed during these cleaning and sterilization processes, avoiding leakage or contamination of liquids and gases, and ensuring that the valve can be restored to its original sterile state after each cleaning. This not only improves product safety, but also improves production efficiency.

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语