Split Butterfly Valve

Aseptic Split Butterfly Valve

Function:

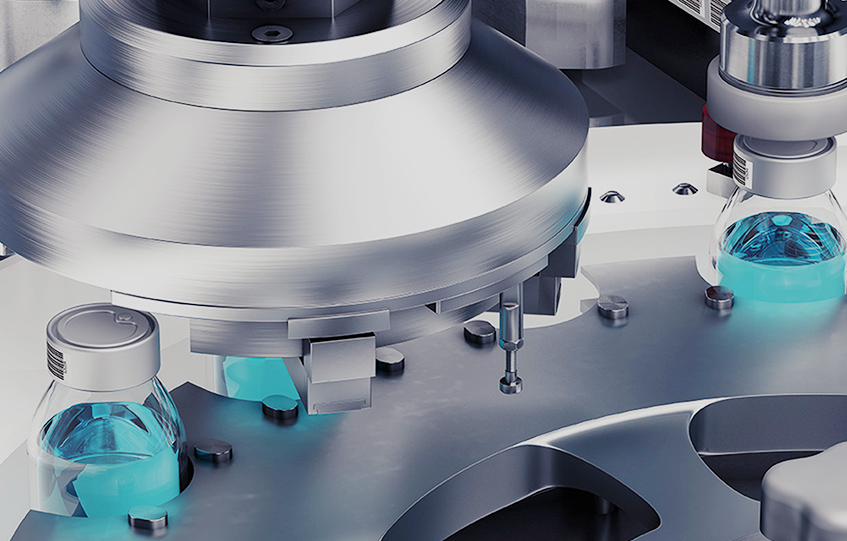

In the pharmaceutical field, various active pharmaceutical ingredients (API) and isolated pharmaceutical intermediates (IPI) are involved in the entire production process. These substances may have certain activity, toxicity and sensitization, and their occupational exposure limits (OEL) are usually lower than 1mg/m3, or there is no publicly credible occupational exposure limit. In addition to the potential health threat to people in close contact, the production process of most substances also needs to be closed and isolated from the uncontrolled environment. The relevant industry regulations have corresponding requirements and guidance for the transportation, transmission and packaging of the above substances in the production process. αβ valves can be used as an effective auxiliary measure to meet the closed processing requirements in the above environment.

Technical principle:

αβ valve technology provides the possibility of transferring powder materials from one device to another in a closed manner, minimizing the exposure of highly active sterile powders to the external environment during the transfer process, establishing a protective barrier between operators and materials to be processed, and also protecting the sterile environment of the materials.

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语