When you don't want your environment to be polluted by the exhaust of pneumatic actuators, you can choose this electric diaphragm valve.

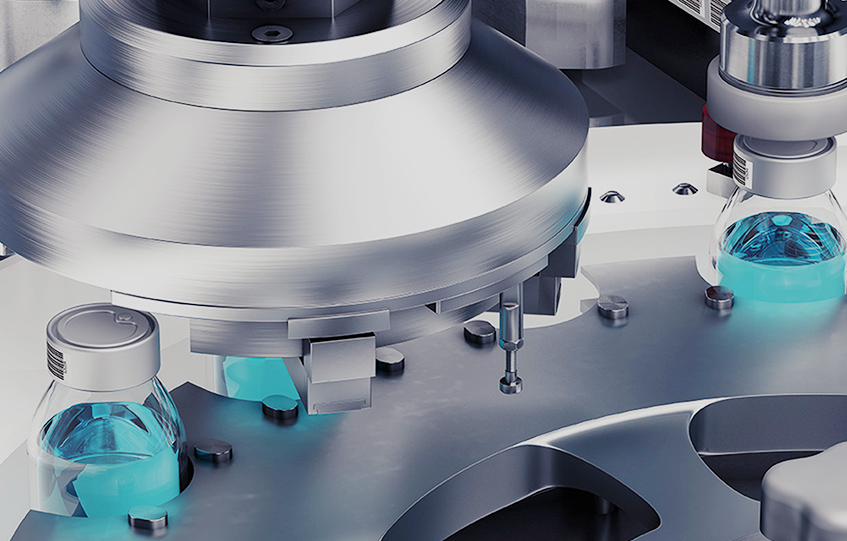

Verified high-performance double diaphragm forged diaphragm valve suitable for strict aseptic processes.

Eling company offers diaphragm valves with different structures and materials to choose from, which can meet the requirements of non application processes or customize your own diaphragm valve. If you have specific needs, please feel free to contact us in a timely manner:

Application areas:

Aseptic diaphragm valves are mainly used for aseptic applications in the pharmaceutical, food, and biotechnology industries. They are suitable for intermediate and final products in ultrapure water (injection water), ultra-high purity chemicals, pharmaceutical and biotechnology industries, food processing, and chemical industries.

By adopting a sealed design and sterile diaphragm technology, we ensure high-quality and pollution-free products. We use compact, lightweight, and easy-to-install two-way valves and customized valve groups to save time and money. We use dedicated valves to improve performance, minimize dead corners, and maximize drainage and cleaning capabilities. By optimizing valves and using high-quality and durable materials, we improve performance and reliability while reducing downtime

Excellent drainage performance, reducing dead corners. The inner surface can be mechanically polished and/or electropolished to Ra 0.4 µ m, allowing for CIP/SIP and sterilization

Compact design, space-saving

OEM customization and flexible design

• Reduce dead corners • Fewer connection points and welds

• Integrate multiple functions in the smallest space possible

• Sealing and isolation between the medium and the actuator

Technical specifications

• Medium temperature: -10 to 100 ° C

• Sterilization temperature: up to 150 ℃

• Environmental temperature: 0 to 60 ℃

• Work pressure: 0 to 10 bar

• Nominal size: DN 4 to 150

• Valve body configuration: multi-port valve body | tank valve body

• Connection type: Welding | Clamp

• Connection standard: ASME BPE DIN can also be customized

• Valve body material: 1.4435 (316L), block material Hastelloy, 904L, 22052504, etc

• Diaphragm material: EPDM | TFM/EPDM

• Compliance: USP | 3A | FDA |

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语