Principle:

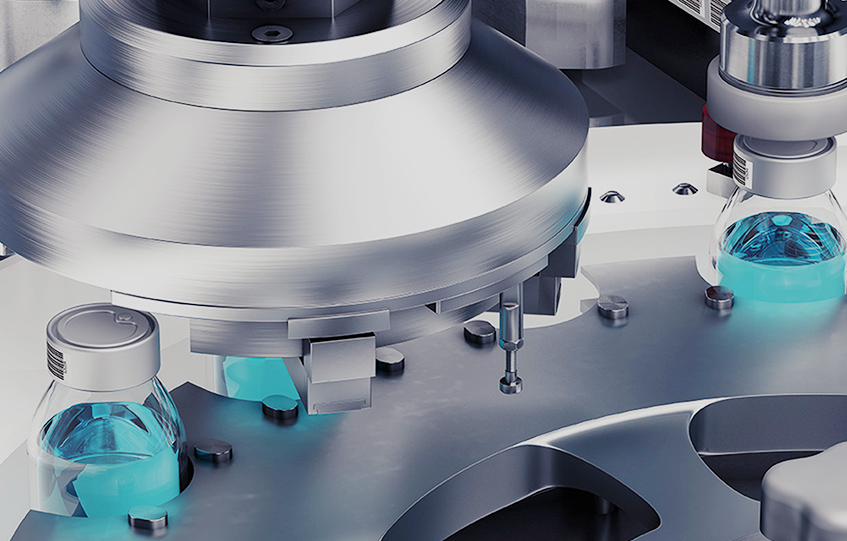

Tube-in-tube heat exchanger is an efficient and robust heat exchange device widely used in pharmaceutical processes to exchange heat between two fluids while strictly maintaining fluid separation. It consists of three tubes nested coaxially inside the tubes, forming two independent flow channels - the hot fluid passes through the intermediate tube, and the cold fluid passes through the inner and outer tubes.

Typical application conditions of PHC:

PHC series products are mainly suitable for cooling water points in pure water and injection water systems, with built-in flow and temperature control systems. Modular design for easy installation.

In standby mode, the cooling water circuit is in the off state, and the heat exchanger can be regarded as a sub circuit in the system. Pure water/injection water will flow through the heat exchanger and return to the main circuit, keeping the heat exchanger and main circuit in a continuous disinfection state.

In cooling mode, the cooling water control valve automatically opens, and the cooling water participates in the cooling work. The water intake flow rate of the water point can be adjusted through the handwheel, and excess pure water/injection water will be returned to the main circuit.

The main characteristics of tube-in-tube heat exchangers

1. Three channel design: Cold and hot fluids flow separately in two channels, minimizing the risk of cross-contamination, which is a key requirement for pharmaceutical production.

2. Compact and modular design: The heat exchanger has a compact structure, and built-in control valves, and does not require electrical or control components.

3. Continuously flowing hot water can keep it in a disinfected state at all times,

4. Efficient heat transfer: The coaxial design supports upstream or downstream configuration, with flow rates ranging from 300L to 2500L and temperature ranges from 85 ℃ to 25/40 ℃

Application in pharmaceuticals

Cleaning of production tools

Low-temperature liquid preparation

Experimental equipment Scope of manual cleaning for valves, fittings, gauges, etc

Advantages of tube-in-tube heat exchangers

Sanitary design: Compliant with GMP (Good Manufacturing Practice), smooth surface, easy to clean (supports CIP/SIP cleaning).

High thermal efficiency: maximizes energy utilization and reduces operating costs.

Low maintenance cost: simple structure, reducing downtime.

Customizable: can be designed according to different flow rates and temperature ranges.

Built-in valve control module, one-click start, easy to achieve the cooling target.

All product contact surfaces have undergone passivation treatment, with a Ra value of less than 0.4um, and can be electrolytic polished

316L stainless steel structure

Provide complete quality documents

Compliant with ASME BPE standards

Patent technology:

One-click control switch, simple and efficient

Automatically drain the partially cooled water (75 ℃ -85 ℃) when taking water

Automatically drain the cooled water (25 ℃ -40 ℃) when turned off

Effectively ensure the safety of operators and water systems

Technical parameters:

• Pure water/injection water interface: 3/4 ~1" TC

• Cooling water interface: 1. 5 " , 2 " , 3 " TC

• Maximum processing traffic: 25,000L/h

• Design pressure: 10 Bar

• Design temperature: 150°C

• Material:

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语