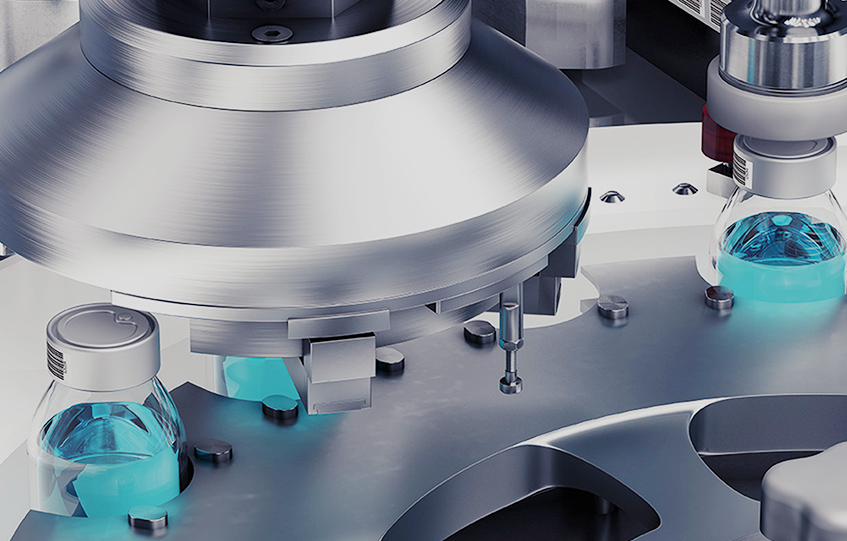

Micro sanitary shell and tube heat exchangers are designed to meet the high-quality requirements and hygiene standards of the pharmaceutical industry. The maximum surface finish of all product contact surfaces is (0.5 µ m) Ra and can be increased to 15 µ in (0.38 µ m) Ra or better through optional electropolishing. Provide single or double tube plates to eliminate the risk of cross-contamination between products and working fluids.

Suitable for single-point cooling, such as bottle washing machines, pool cooling points, etc.

Advantage:

The structural design of the compact arrangement of micro tube bundles maximizes heat transfer

Coefficient, small size, lightweight, heat transfer rate, suitable for applications with limited installation dimensions.

All liquids can be completely emptied from the lowest outlet.

• Double tube plate design to avoid cross-contamination

• Full emptying design, no dead corners, no material residue

• Allow an average temperature difference of 70 ° C between hot and cold fluids

• Made entirely of 316L stainless steel material

• Connection method: Tube side: Chuck connection

Shell process: NPT thread or chuck connection

• Electrolytic polishing of the inner surface of the tube: Ra<0.5 electric polishing or machine polishing

• Compliant with FDA and CGMP requirements

Typical applications:

• Use point cooling or heating

• Injection water (WFI) cooling

• Clean steam condensation and cooling

• Temperature control of medication solution

• Product Sampling

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语