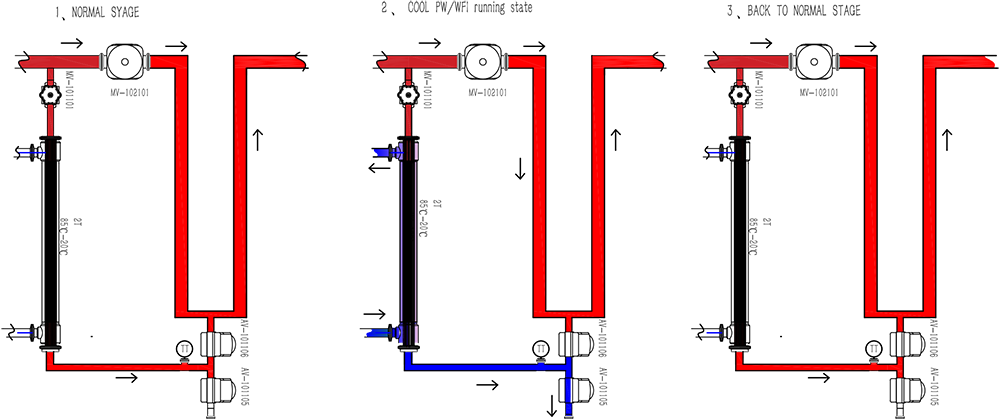

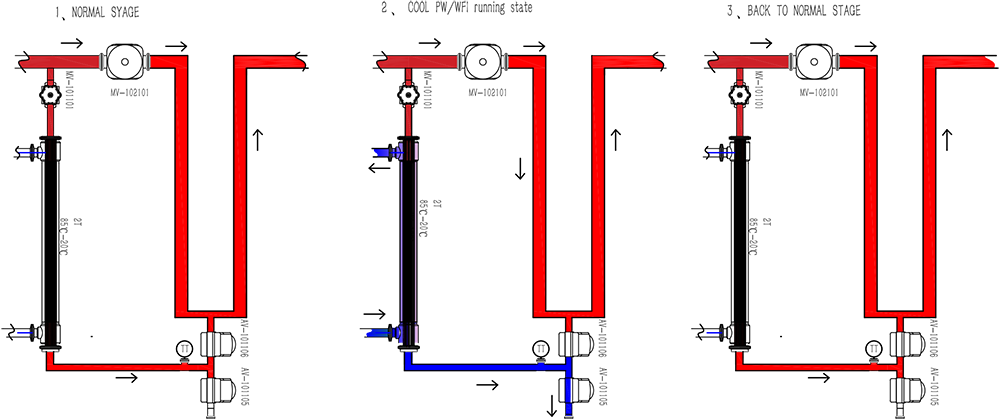

The Eling brand heat exchange system can regulate the flow and temperature of injection water/purified water to achieve cooling or heating effects,

Compliant with strict FDA, USP ASME BPE, and GMP regulations in the pharmaceutical industry. When the system is not working, the hot water in the main circulation can be continuously disinfected to meet most working conditions and there are multiple process options available.

Design features:

Dispense flow rates up to 4000L/H

Fully drainable on product side, with no dead legs

Easy to install, operate and maintain, Regulating header valve ensures desired flow rate, even if main loop pressure varies.

Full performance test done on every POU

CIP and SIP capable

Fully automated (manual operation available)

Touch screen HMI with intuitive software to view process parameters & system operation

Cool WFI/PW from 8S°C to 20°C

Hot WFI/PW from 20°C to 8S°C

Design Features

Advantages:

Touch screen HMI with intuitive software to view

process parameters & system operation

The temperature can be set by yourself and adjusted precisely.

Fully automated (manual operation available)

CIP and SIP capable

Easy to install, operate and maintain

Fully drainable on product side, with no dead legs

Documentation

FAT Report (Component Certs & MTR’s, Orbital Weld Logs, Inspection, Leak Test, Passivation,

Performance Reports)

Quality Assurance Plan (QAP) QAP

Design Qualification (DQ) DQ

Install, Operating & Maintenance Manual

POU pipeline diagram

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语