Rapid Transfer System Port

RTP Lifting Transfer Trolley

Automatic transfer trolley

One trolley with two transfer modes can realize the quick switching between Beta container and Beta Bag. The lifting height can be preset in advance from 1000 meters to 2 meters. The controller is integrated in the handle of the trolley to make the operation more comfortable. It is equipped with silent anti-static wheels.

Maximum lifting capacity 50 kg

Large-capacity lithium battery can meet the continuous operation for 5-6 hours.

Vehicle weight 30KG

Dimensions: 1000*700*(1000-2000)

Structural composition

- Frame: Generally made of high-strength metal materials, such as stainless steel or aluminum alloy, to ensure the load-bearing capacity and stability of the trolley, while having good corrosion resistance and durability.

- Lifting mechanism: The electric lifting system is easy to operate and easy to control;

- Traveling mechanism: The silent anti-static wheels can travel smoothly on the ground, realizing the front, back, left, right, up and down movement of the trolley.

- Control system: The single-chip microcomputer is the core control unit, and the precise control of the lifting and lowering of the trolley is realized through programming. At the same time, it is also equipped with sensors and operation buttons to detect the position and status of the trolley and receive instructions from the operator.

Working Principle - Lifting principle: When the goods need to be raised or lowered, the motor power source of the lifting mechanism is started. The power source drives the electric push rod component in the lifting device to move, thereby driving the cargo platform of the trolley to rise or fall, realizing the lifting and lowering operation of the goods.

- Transfer principle: The operator sends instructions to the motor of the walking mechanism through the control system or manual operation button, and the motor drives the wheels to rotate, so that the trolley drives along the preset track or path to the specified position. During the driving process, the control system will monitor the position and status of the trolley in real time to ensure the safety and accuracy of the trolley.

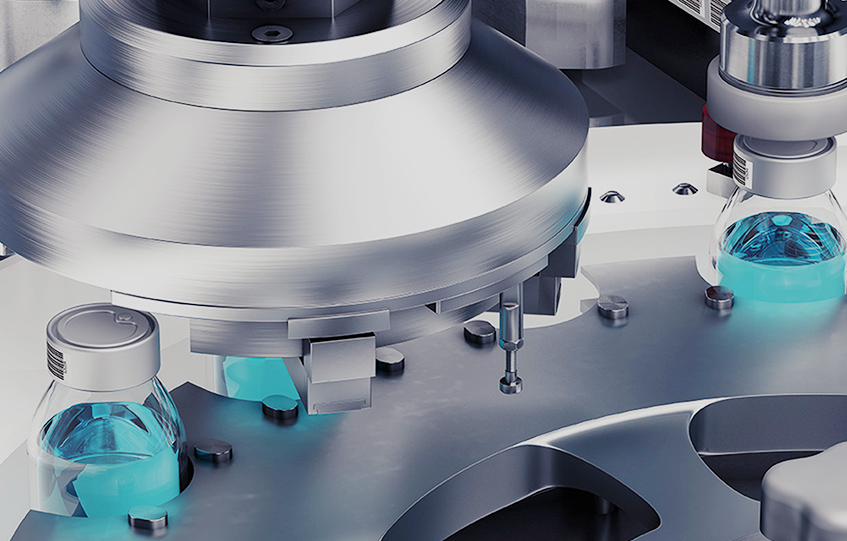

Application field

- Pharmaceutical industry: In the process of drug production, RTP Beta containers and BetaBag and other equipment used for transporting RTP aseptic transfer ensure the safety of drugs during transportation.

Advantages - Improve production efficiency: Automated lifting and transfer functions can reduce the time and labor intensity of manual handling and operation, and improve the efficiency of production and logistics.

- Ensure cargo safety: Precise lifting and transfer control, as well as the setting of safety protection devices, can effectively avoid damage to cargo and safety accidents during transfer.

- High flexibility: The structural design and control system of the trolley can be customized according to different application scenarios and customer needs, with high flexibility and adaptability.

英语

英语 俄语

俄语 阿拉伯语

阿拉伯语 西班牙语

西班牙语